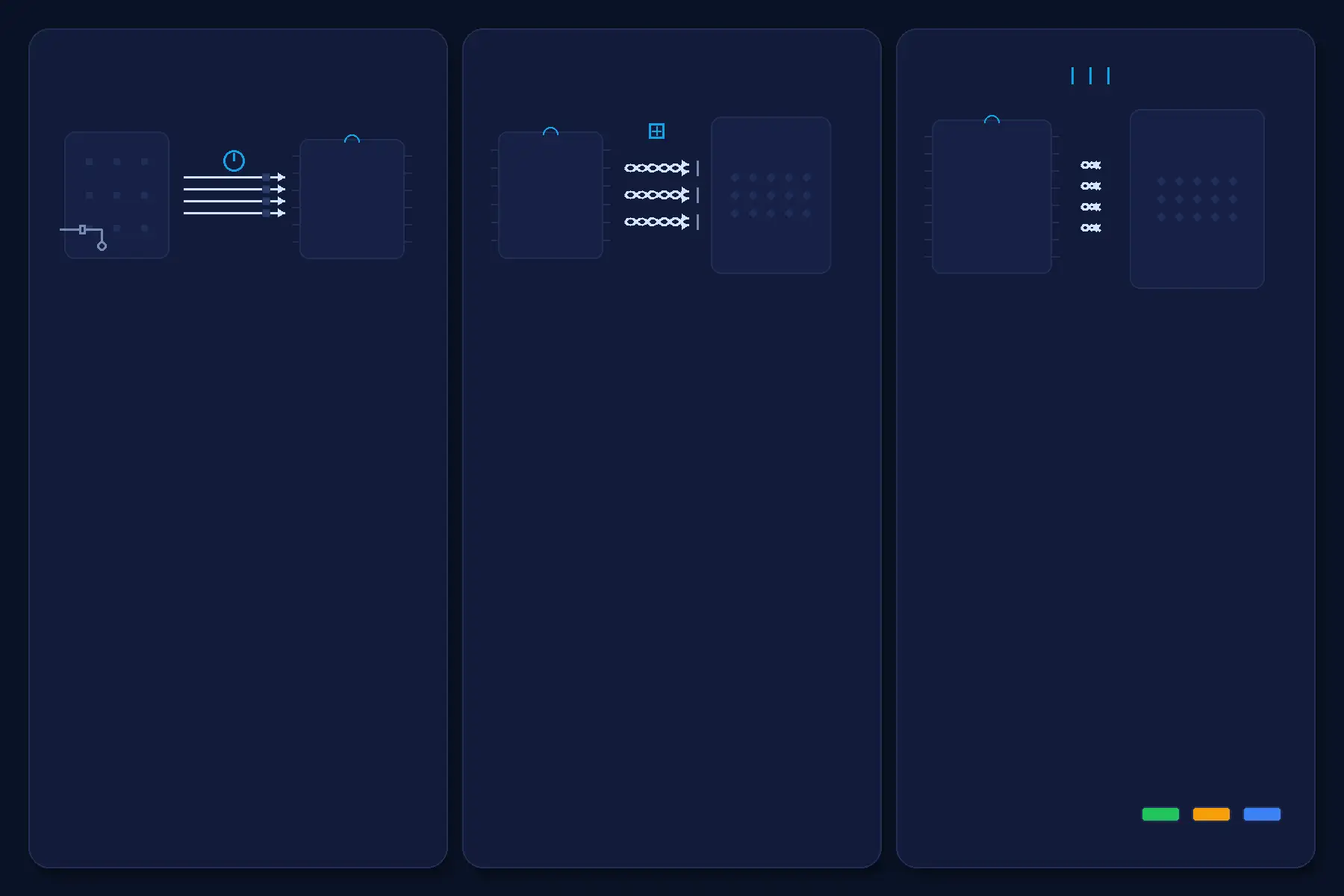

ADC Interfaces: SPI vs LVDS vs JESD204 — Which should I use?

Global electronic component supplier ERSAELECTRONICS: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

Which ADC Interface Should I Use? SPI vs LVDS vs JESD204

Got fs, bits, channels, your host (MCU/FPGA), and need deterministic latency? Use the flow below to pick the right ADC interface.

- SPI — Simple and MCU-friendly; up to tens of Mbps; best for few channels / lower rates.

- LVDS — Mid-to-high speed, differential and source-synchronous; common on fast SAR/pipeline ADCs.

- JESD204 (B/C) — Very high throughput, multi-channel, deterministic latency, scalable; requires FPGA/SerDes.

Want to learn What is an ADC? Read the definition →

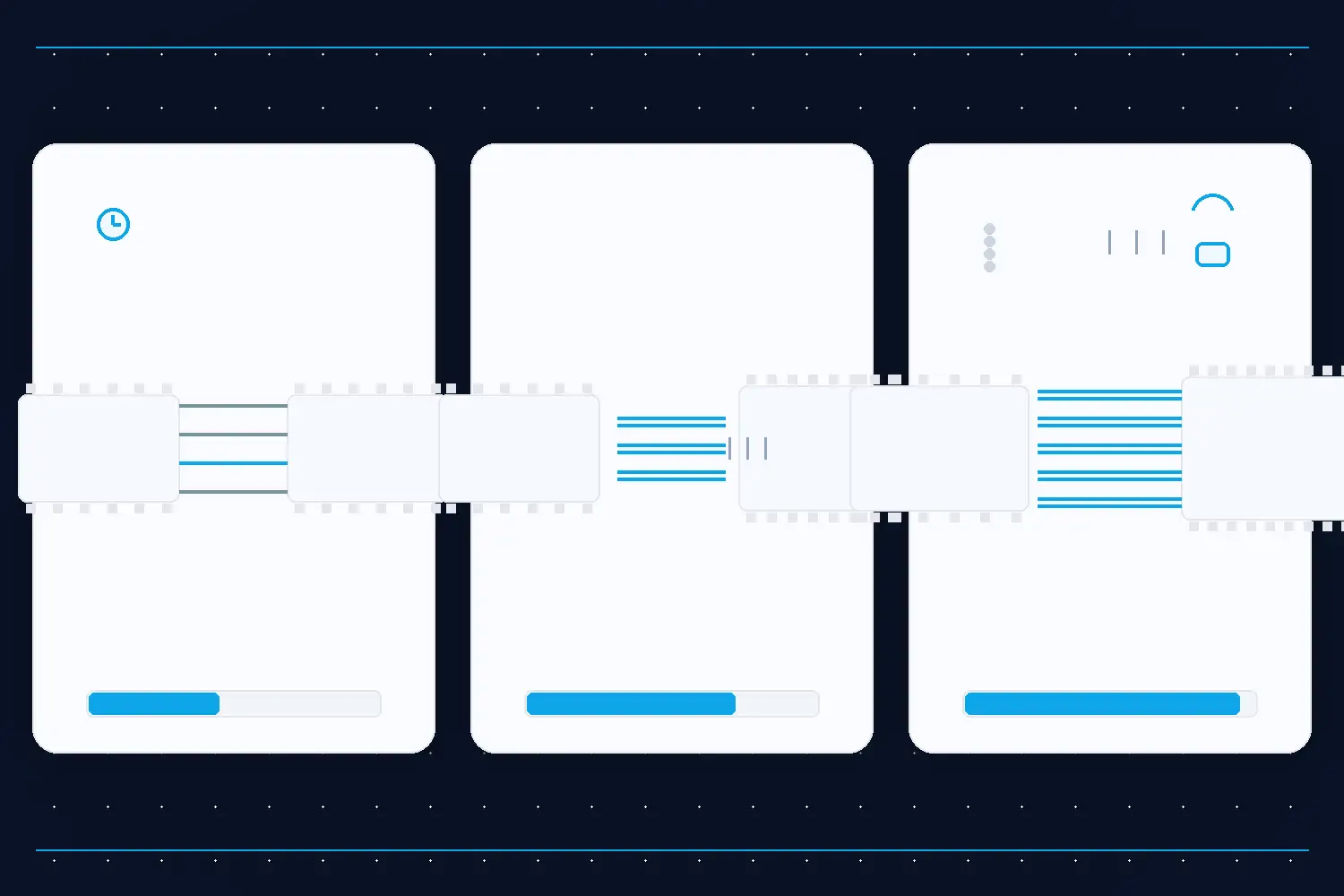

Quick Picker — Decision Flow & One-Line Math

Have answers to four quick questions? Follow them to a safe interface choice.

fs × bits × channels > ~30–50 Mbps?(JESD204 uses SYSREF and multi-lane alignment for deterministic latency.)

Example — 2ch × 14-bit × 5 MS/s ⇒ 140 Mbps raw; with 8b/10b ≈ 175 Mbps; +20% headroom ⇒ ≈ 210 Mbps → LVDS turf.

- SPI: Watch MCU SCLK ceiling and DMA; long or cross-board wires are risky.

- LVDS: Keep 100 Ω differential impedance, length match, and place termination correctly.

- JESD204: Calculate lane rate × lane count; Subclass/SYSREF drive determinism.

SPI — When to Use, Limits, Layout & Bring-up

3.1 When SPI makes sense

- Low / mid-speed capture, single or few channels; direct MCU connection.

- Prototype / small-batch builds need a fast bring-up with low BOM and tooling cost.

- Lightweight integration with firmware/GUI, no FPGA/SerDes required.

3.2 Throughput limits & safe margin

Quick estimate (SPI uses E_coding ≈ 1.00): Required SCLK ≈ (fs × bits × channels) / E_coding

- Leave 10–20% headroom for framing, alignment and device wait states.

- Typical MCU sustainable SCLK spans ~10–40 MHz (higher is possible but board routing, load and DMA overhead apply).

- Long runs / cross-board jumpers / noisy environments lower the practical SCLK ceiling.

Example: 16-bit × 1 ch × 500 kS/s → 8 Mbps raw; +20% headroom → ≈9.6 Mbps SCLK ⇒ SPI is feasible on many MCUs if routing is short and clean.

3.3 Layout — Do

- Keep traces short, continuous reference plane; ensure a clear clock return path.

- Place 22–47 Ω source series resistors on SCLK/MOSI near the driver to tame ringing/overshoot.

- Use proper near-receiver termination/mode per datasheet (pull-ups/downs, Schmitt options).

- Isolate from switchers/motors; if you split grounds, single-point tie near the ADC.

3.3 Layout — Don’t

- No long breadboard leads or ribbon cables for high-edge SCLK.

- Avoid casual level shifters between 1.8↔3.3 V — they add skew and edge distortion.

- Don’t meander CS/DRDY — sloppy routing eats setup/hold margins.

3.4 Bring-up checklist (step-by-step)

- Power & reference: verify Vref decoupling and ground bounce (scope the ripple).

- Probe the link at low SCLK: read the fixed device ID/version register first.

- Match SPI mode: set CPOL/CPHA per datasheet; confirm bit order (MSB/LSB).

- Code format sanity: apply a static step input and check Straight / Offset-Binary / Two’s-Complement decoding.

- Edge timing margin: raise SCLK gradually; measure MISO sampling window (LA/scope).

- DMA / ISR: enable circular DMA or double buffer; watch for overrun / dropped samples.

- Integrity checks: enable frame header/CRC/alignment flags if supported.

- Soak test: run 10–30 min under thermal/load variation; track code jitter and error counters.

3.5 Common pitfalls (symptom → fix)

- Waveform looks fine but codes are wrong: CPOL/CPHA or bit order mismatched to the timing diagram.

- Sporadic misalignment / lost codes: CS/DRDY setup/hold violated; SCLK edge too sharp → add series resistors.

- Random codes after long/cross-board runs: poor edge integrity → buffer, series damping, or move to differential.

- I/O domain mismatch: ADC and MCU voltage levels differ → use a proper same-domain pairing or a spec’d translator.

3.6 When NOT to use SPI

- When

fs × bits × channelsapproaches or exceeds your MCU’s sustainable SCLK (incl. DMA overhead and 10–20% headroom). - When you need deterministic latency or multi-device sync (→ prefer JESD204).

- When routing is long or EMI is heavy and you can’t guarantee edge integrity (→ prefer differential LVDS/JESD).

LVDS — Differential, Source-Synchronous, Mid-to-High Speed

4.1 When LVDS fits

- Tens to hundreds of Mbps per pair; parallel data pairs (often DDR) for aggregate throughput.

- Differential noise immunity and lower emissions; better for longer on-board runs or noisy environments.

- Source-synchronous capture (forwarded DCO + DATAx) is friendlier than MCU-sampled SPI at these rates.

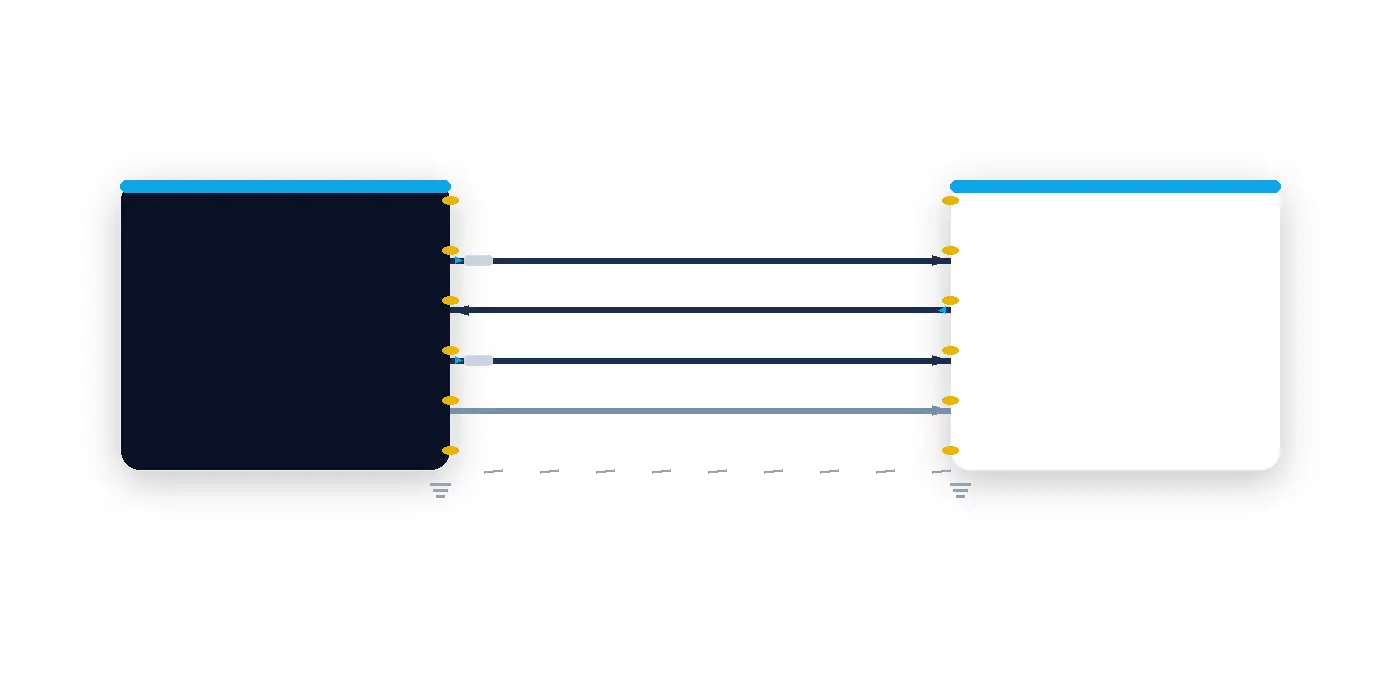

4.2 System shape

ADC forwards a differential clock (DCO+/−) plus one or more DATA+/− pairs (often DDR). The receiver (FPGA or dedicated LVDS RX) performs bit/word alignment per channel, then buffers to FIFO/processing. No heavy line coding (usually no 8b/10b), but frame/word markers may exist.

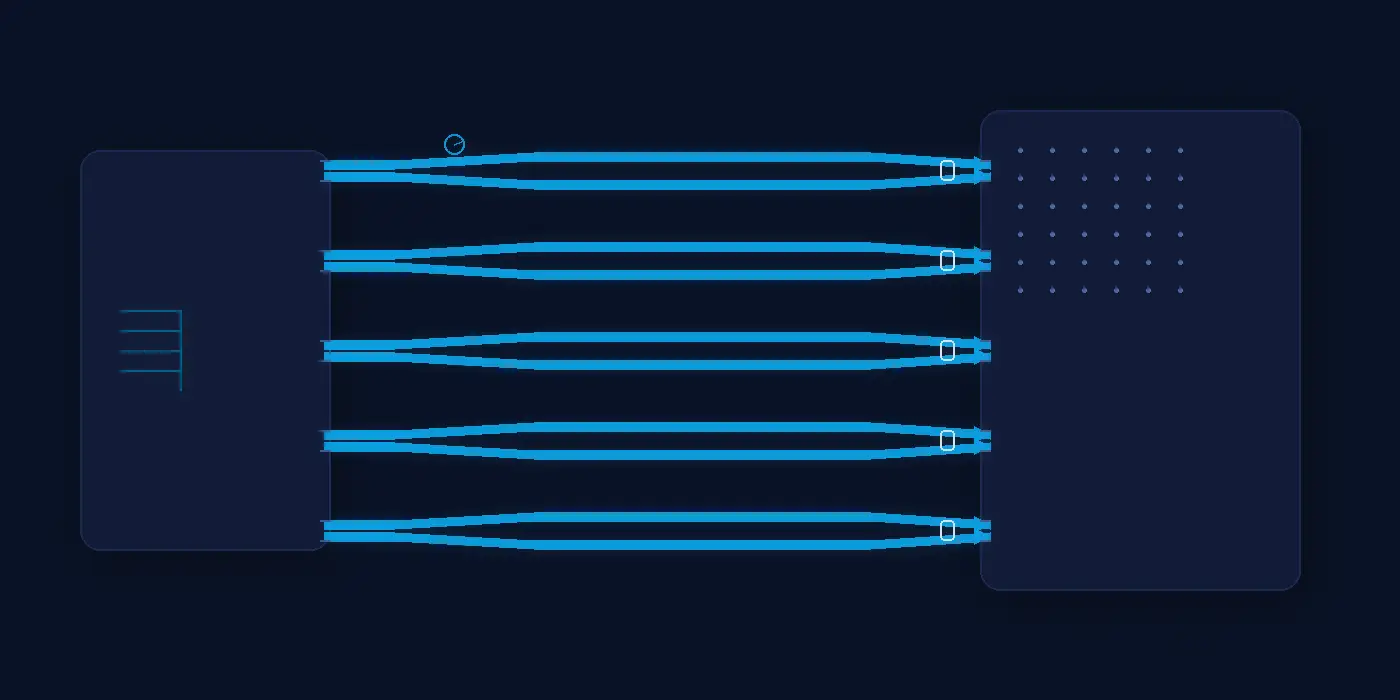

4.3 Throughput & lane math (one-liners)

T_raw = fs × bits × channelslane_rate ≈ T_raw / N_pairs(LVDS coding efficiency ≈ 1.00)- For DDR data:

f_DCO ≈ lane_rate / 2 - Unit interval:

UI = 1 / lane_rate; keep intra-pair skew ≲ 10–20% UI. - If the ADC uses a serializer factor S (e.g., 7:1/14:1), compute N_pairs and f_DCO per the datasheet mapping.

4.4 Layout — Do

- Route 100 Ω differential pairs, tightly matched length; control intra-pair skew within your UI budget.

- Maintain a continuous reference plane; pre-plan return paths when crossing layers or plane splits.

- Place termination at the receiver (or enable internal 100 Ω) close to pins.

- Use paired vias, minimize stubs (back-drill/blind-buried if needed).

4.4 Layout — Don’t

- No test pads/fly-wires inside a pair — they create stubs.

- Avoid crossing plane splits or running parallel to noisy switching rails.

- Don’t mismatch pair lengths or swap P/N; both collapse eye opening.

4.5 Bring-up checklist

- Lock DCO & data: verify DCO frequency/duty and DDR relationship to DATAx (scope/LA/ILA).

- Frame/word alignment: enable the device’s align mode or implement bit-slip/word-align in the FPGA.

- Lane matching: align channels (bit/word) and measure lane-to-lane skew.

- Jitter margin: check sampling edge margin; tune input delay/phase on the FPGA; reduce on-board noise sources if needed.

- Integrity checks: run known patterns (fixed/step codes) and track error/lost-frame indicators.

- Soak test: 10–30 min over temp/load; ensure no intermittent misalignment.

4.6 Common pitfalls

- P/N swaps or pair crossovers → inverted/garbled codes.

- No/incorrect termination or wrong location → amplitude issues, crosstalk/EMI rise.

- Excessive intra-pair or lane-to-lane skew → collapsed eye, random bit errors.

- Poor DCO duty/jitter → reduced sampling window, intermittent faults.

4.7 When to step up to JESD204

- More channels or rising aggregate throughput demanding scalability.

- Off-board/cable links or deterministic latency and system-wide synchronization.

- Planned lane aggregation or distributed acquisition architectures.

JESD204 (B/C) — Ultra-High Throughput, Multi-Channel, Deterministic

5.1 When JESD204 makes sense

- Very high aggregate throughput and/or many channels beyond LVDS comfort.

- Deterministic latency and fleet-wide synchronization needs (Subclass with SYSREF/LMFC).

- Scalable multi-lane SerDes links; typical host is an FPGA/SoC with SerDes.

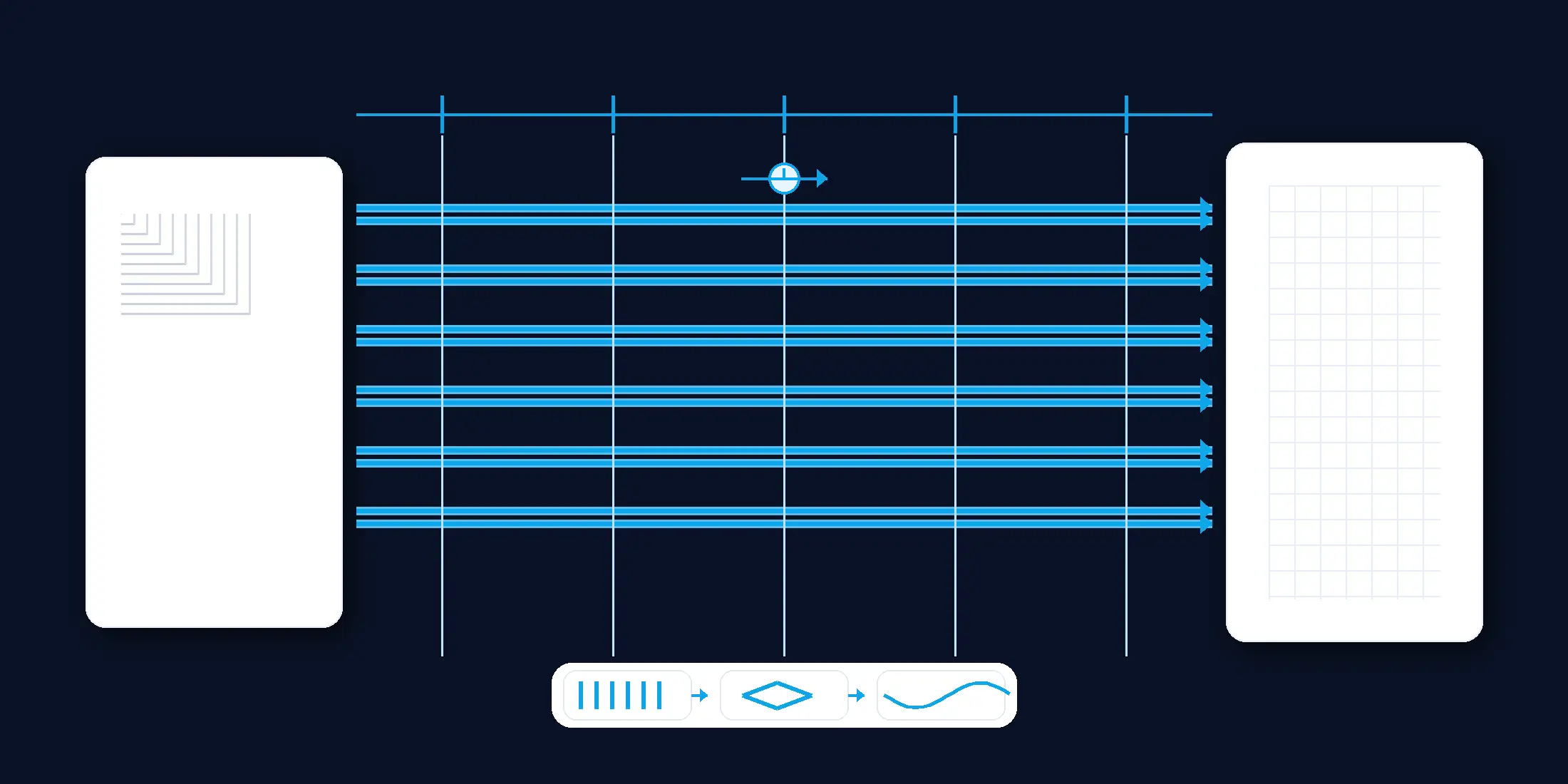

5.2 Concepts at a glance

- Multi-lane SerDes aggregates throughput; trade lane rate vs lane count.

- Link bring-up stages: CGS → ILAS → DATA.

- Determinism: SYSREF/LMFC (Subclass) for fixed, repeatable latency and device alignment.

- Coding efficiency: 8b/10b ≈ 0.80; 64b/66b ≈ 0.97 (JESD204C supports higher efficiencies and rates).

5.3 Lane-rate math (one-liners)

Tip — Plan lane-to-lane skew and LMFC alignment windows when choosing N_lanes.

5.4 Layout & clocking — Do

- Route controlled-impedance differential pairs, matched length, continuous return paths.

- Use paired vias, keep stubs minimal (back-drill where needed).

- Distribute low-jitter clocks and SYSREF symmetrically; document LMFC relations.

- Mind PI/SI: SerDes rail decoupling, plane integrity, isolation from RF/analog front-ends.

- Simulate eye/channel if possible (CTLE/DFE/pre-emphasis budgeting).

5.4 Layout & clocking — Don’t

- Don’t cross plane splits or run near switching/high-current paths.

- Don’t treat SYSREF as a casual GPIO; asymmetry kills determinism.

- Don’t place test pads near SerDes pins; avoid return-via omissions.

5.5 Bring-up checklist (CGS → ILAS → DATA)

- Clock & SYSREF up: verify ref-clock jitter, SYSREF edges, and LMFC phase relations.

- CGS: achieve code-group sync; confirm character alignment stability.

- ILAS: exchange parameters; match lane IDs, octets, scrambling, subclass.

- DATA: enable lane alignment/deskew; align all lanes to the same LMFC.

- Determinism: measure end-to-end latency; confirm cross-reset repeatability.

- Error monitors: track bit/frame/multiframe errors; stress temp and supply noise.

5.6 Common pitfalls

- SYSREF/LMFC mis-config or asymmetric routing → no determinism or drift across resets.

- Mismatched coding/mapping (8b/10b vs 64b/66b, scrambling, F/K characters) → CGS/ILAS loops.

- Excessive lane skew → lanes won’t align; intermittent bit errors.

- Poor PI/SI → eye closure, rising BER; SerDes rail ripple causes wander.

5.7 When NOT to use JESD204

- Your host is MCU-only (no SerDes/FPGA capability).

- Aggregate throughput and channel count are modest (SPI/LVDS suffice).

- Strict cost/power budgets rule out SerDes and clock-tree complexity.

Practical Patterns — From Requirements to Interface

FAQ — Interface Selection

Related Articles

- ·ICD Electronics: Tiny Lightning, Relentless Reliability

- ·Smart Pill Dispensing Electronics: From Missed Doses to Mission Control

- ·Conditional Access Module (CAM): The Pay-TV Gatekeeper Engineers Actually Enjoy Reading About

- ·NC Formula Semiconductor: The Blockbuster Guide You Didn’t Know You Needed

- ·Electrosurgery Electronics: Turning RF Into a Surgical Superpower

- ·Endoscopic Imaging Electronics: Tiny Optics, Big Picture

- ·Instrument Cluster: The Dashboard Wizard That Makes You Feel Like Iron Man

- ·X-ray & CT Electronics: From Kilovolts to Reconstruction

- ·MRI Core Electronics: From Quench to K-Space

- ·OKL Series PoL DC/DC Converters: The Bite-Size Power Bricks That Keep Your Board Cinematic

.png?x-oss-process=image/format,webp/resize,h_32)